DADI can provide upgrading service of unattended intelligent system for stacker reclaimer according to user's demand. Through the equipment automatic driving obstacle avoidance function, relying on laser scanner and other corresponding hardware and software support, we can complete the collection and analysis of data information for the entire material yard, so as to realize the automatically and accurately reclaiming of equipment, and to achieve the following goals:

★ Improve the labor environment, reduce labor intensity;

★ Reduce human influence and labor cost;

★ Improve the automation degree of stacker reclaimer and stabilize production operation.

★ Improve the intelligent operation management level of stacker reclaimer.

★ Maintain the technological advancement of the industry.

Key Features & Advantages

Designed for harsh environments: Our stacker reclaimer operates stably in temperatures from -50°C to +50°C.

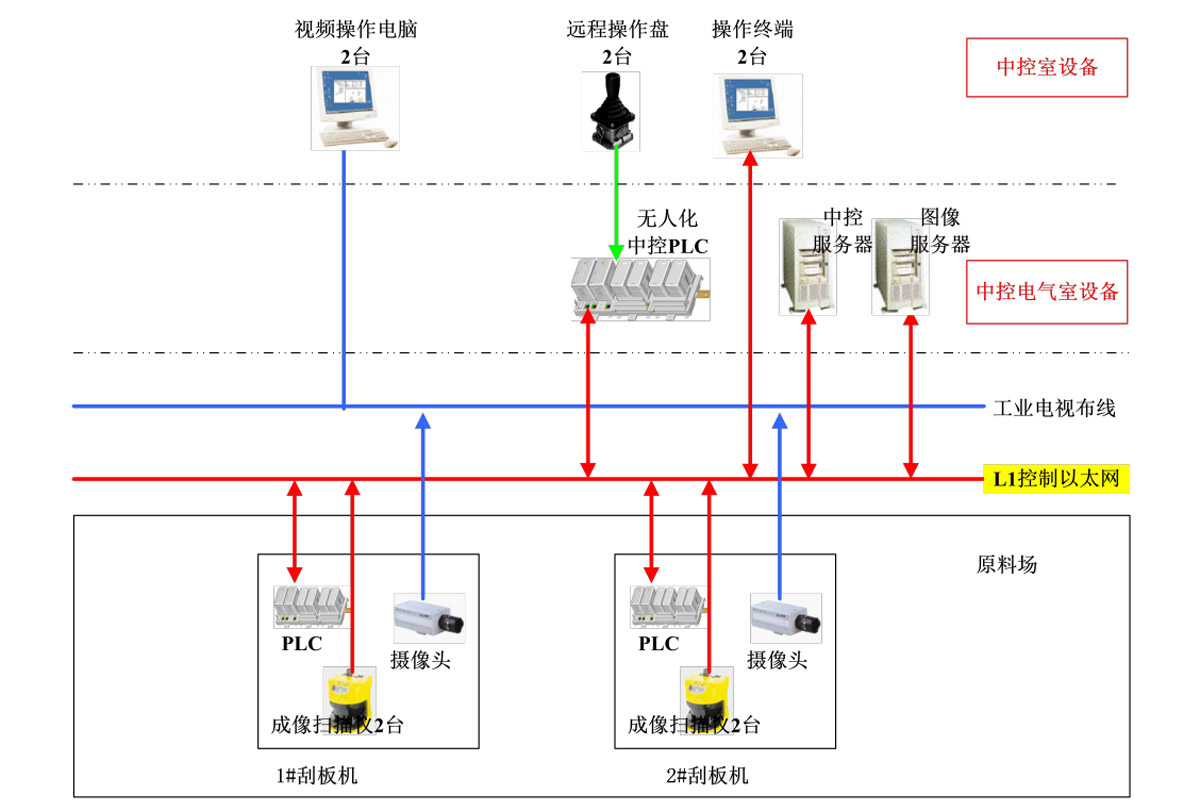

Intelligent Control: Equipped with PLC system for fully automated unmanned operation.

Customizable Capacity: Handling capacity ranges from 500t/h to 5000t/h tailored to your yard size.

Low failure rate, low maintenance cost, and low operating cost.

Technology originated from Germany, refined through years of innovation, achieving advanced and proven maturity.

Applications

Widely used in Steel Plants for raw material handling.

Essential for Thermal Power Stations coal handling systems.

Optimized for Cement Plants limestone pre-homogenization.

Best solution for bulk material conveying and handling.

Efficiently stacks and reclaims bulk ores and minerals at mining sites.

Used for stacking and reclaiming fertilizers, potash, and phosphate materials.

Essential for stockpiling and reclaiming bulk materials in port operations.

Technical & Material Details

Main structure made of high-strength low-alloy steel (Q345B, Q355E) for durability.

Critical components are made of imported wear-resistant materials (HARDOX) to ensure a long service life.

Key components sourced from top-tier brands: SEW reducers, SIEMENS motors, SKF bearings, Ketten-Wulf chains, and Schneider electrics.

Service & Support

Global Installation Service: We dispatch engineers to your site (Vietnam, Indonesia, etc.) for installation and commissioning.

24/7 Remote Technical Support and lifetime spare parts supply.

FAQ - Mini Version

Q: Can you customize the rail gauge?

A: Yes, we customize based on your existing civil work.

Q: What is the delivery time?

A: Typically 3-5 months depending on specifications.

Q: Is the equipment explosion-proof?

A: Yes, our stacker reclaimer is designed to be explosion-proof for operation in hazardous environments.

After submitting the information,

there will be an engineer to contact you