2024

Bridge-Type Scraper Reclaimer Solutions for Efficient Bulk Material Handling

27 Jan.2026

In large-scale industrial operations, bulk material handling is rarely just a supporting process—it often determines overall production stability. Industries such as steel, mining, cement, power generation, and port logistics rely on continuous, well-controlled material flow to keep downstream systems running smoothly.

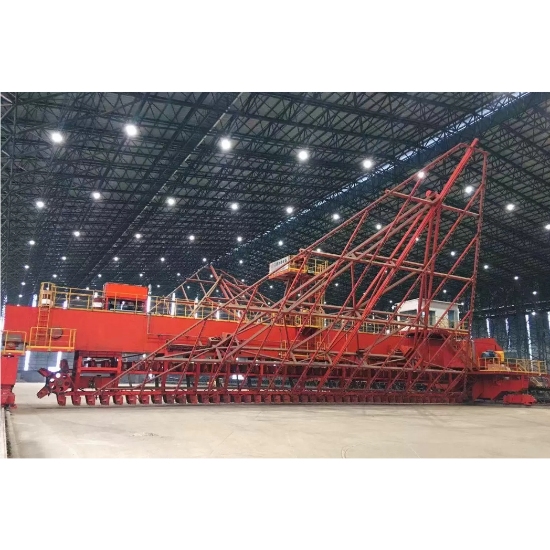

For longitudinal blending stockyards, the bridge-type scraper reclaimer has proven to be a reliable and efficient solution. Designed for high-capacity reclaiming and consistent blending, it helps operators manage large volumes of bulk materials while maintaining stable composition. With extensive experience in bulk material handling systems, Dadi Engineering provides bridge-type scraper reclaimer solutions that focus on long-term operational performance rather than short-term output alone.

Understanding the Bridge-Type Scraper Reclaimer

A bridge-type scraper reclaimer is a heavy-duty reclaiming machine commonly installed in longitudinal blending stockyards. It works together with a stacker, which builds stockpiles in layers. The reclaimer then recovers material continuously across the pile width, ensuring a steady and well-blended output.

This type of equipment is suitable for handling a wide range of bulk materials, including:

Iron powder

Lump ore

Coal

Flux

Pellets

Coke and similar materials

Its bridge structure and scraper system allow it to operate efficiently even in wide stockyards, where stable reclaiming and blending quality are critical.

Working Principle and Operation Mode

Designed for Longitudinal Blending Stockyards

In a typical system, the stacker builds the stockpile using layered stacking methods. This stacking pattern lays the foundation for effective blending during reclaiming.

Flexible Forward and Backward Reclaiming

The bridge-type scraper reclaimer with double harrow travels along rails installed on both sides of the stockyard. It can move forward or backward to reclaim material from different directions, making it possible to:

Reclaim material from both the front and rear of the stockpile

Carry out stacking and reclaiming at the same time

Maintain continuous material supply without interrupting yard operations

In real production environments, this flexibility significantly improves stockyard utilization and reduces idle time for downstream conveyors and processing systems.

Key Technical Parameters

Dadi’s bridge-type scraper reclaimer solutions are engineered to cover a wide range of operational requirements:

Material Type: iron powder, lump ore, coal, flux, pellet, coke, etc.

Reclaiming Capacity: 500–3200 t/h

Rail Span Range: 30–60 m

These parameters allow the equipment to be adapted to different yard sizes, material characteristics, and production capacities, whether for medium-scale plants or large industrial complexes.

Practical Advantages in Daily Operation

From an operator’s point of view, the value of a bridge-type scraper reclaimer lies in its performance over years of continuous use:

High Reclaiming Capacity with Stable Material Flow

The system delivers large reclaiming capacity while keeping material flow smooth and predictable. This stability helps reduce load fluctuations in belt conveyors and downstream equipment.

Effective Blending with Minimal Composition Fluctuation

Layer-by-layer reclaiming ensures good homogenization of materials. For industries like steel and cement, this directly contributes to more consistent product quality and easier process control.

Smooth and Reliable Operation

The mechanical design emphasizes stability and durability. In practice, this means fewer unexpected shutdowns and more reliable long-term operation under heavy-duty conditions.

Low Operating and Maintenance Costs

Robust components and optimized structure reduce wear and maintenance frequency, helping operators control lifecycle costs.

High Level of Automation

Modern control systems allow for automated operation, remote monitoring, and even unattended running. This not only reduces labor intensity but also improves safety and operational consistency.

Typical Application Industries

Bridge-type scraper reclaimers are widely used in:

Steel plants

Mining and mineral processing facilities

Cement production lines

Thermal power plants

Port and bulk material terminals

In these industries, the ability to handle large volumes while maintaining blending quality makes the bridge-type scraper reclaimer a key part of the material handling system.

Why Dadi Engineering?

Dadi Engineering focuses on bulk material handling solutions that are built around real project requirements. Rather than offering standardized equipment alone, Dadi emphasizes engineering design, system integration, and long-term reliability.

Key strengths include:

Extensive experience in bulk material handling engineering

Equipment designed for demanding industrial environments

Solutions tailored to specific stockyard layouts and capacities

Strong focus on automation, safety, and operational stability

More about Dadi Engineering can be found here:

https://en.cndadiem.com/about.html

Frequently Asked Questions (FAQ)

1. What materials are suitable for a bridge-type scraper reclaimer?

The equipment is suitable for iron ore, coal, coke, pellets, flux, and other bulk materials commonly used in industrial production.

2. How does the system achieve good blending performance?

Blending is achieved through layered stacking combined with controlled, full-width reclaiming, which minimizes composition fluctuations.

3. Can the equipment operate without constant supervision?

Yes. With advanced automation and control systems, the reclaimer can operate with minimal human intervention, improving safety and efficiency.

4. How is reclaiming capacity selected?

Capacity depends on yard size, material characteristics, and downstream demand. Dadi provides engineering support to determine the most suitable configuration.

5. Is maintenance complicated?

The design focuses on reliability and accessibility, making routine inspection and maintenance straightforward for operating teams.

Conclusion

For industrial operators seeking efficient and reliable bulk material handling, the bridge-type scraper reclaimer remains a proven solution for longitudinal blending stockyards. Its ability to deliver high reclaiming capacity, stable material flow, and effective blending makes it a valuable asset in large-scale operations.

With solid engineering experience and a focus on practical performance, Dadi Engineering provides bridge-type scraper reclaimer solutions that support long-term operational efficiency, safety, and consistency. For projects where reliability and blending quality matter, this solution offers a dependable choice.